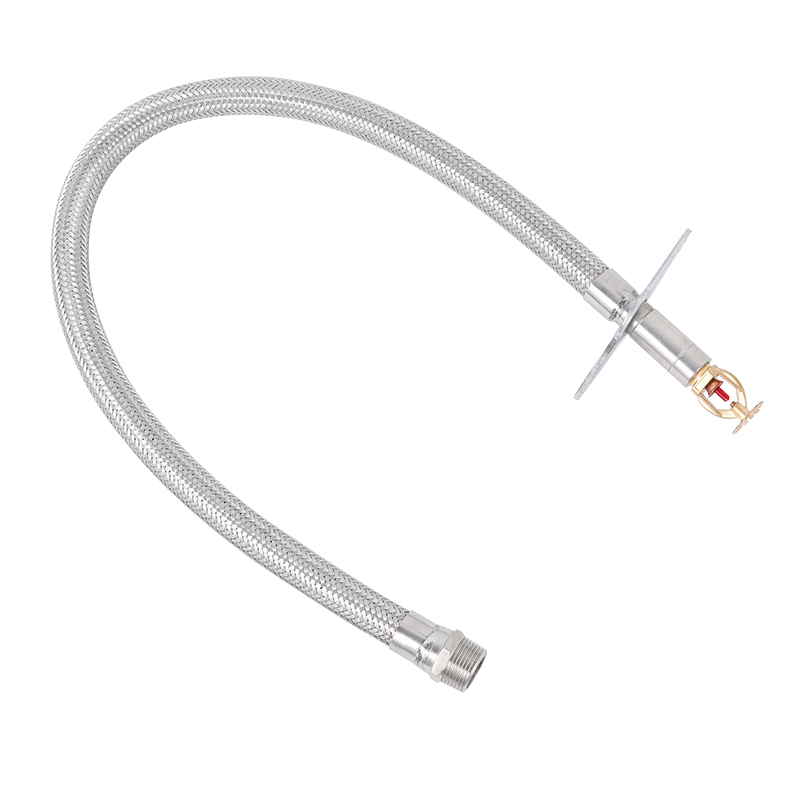

Flanged resiliend heke belofo Grooved resiliend heke valve

| Bophara ba lebitso (mm) | Seaplane se sebetsang | Mocheso o sebetsang | Khatello ea ho sebetsa (PN) | ||

| Intshi | mm | metsi | 0-80 ℃ | Flanged | Grooved |

| 2” | 50 | 10/16 | 16 | ||

| 2 1/2 " | 65 | 10/16 | 16 | ||

| 3” | 80 | 10/16 | 16 | ||

| 4” | 100 | 10/16 | 16 | ||

| 5” | 125 | 10/16 | 16 | ||

| 6” | 150 | 10/16 | 16 | ||

| 8” | 200 | 10 | 16 | ||

| 8” | 200 | 16 | 16 | ||

Litšobotsi tsa melemo:

Setulo sa valve se ka tlase

Hangata valve ea heke ea setso e koaheloa ka groove ka tlase ho valve ka lebaka la lintho tse tsoang linaheng tse ling tse kang majoe, li-blocks tsa lehong, samente, likotoana tsa pampiri le li-sundries ka mor'a hore pipe e hlatsoe ka metsi.Ho bonolo ho etsa hore e se ke ea koaloa ka thata le ho etsa ho lutla ha metsi.Botlaaseng ba valve ea heke ea resiliend e nka moralo o tšoanang o tlase o bataletseng joalo ka phala ea metsi, eo ho seng bonolo ho baka litšila le ho etsa hore mokelikeli o se ke oa thijoa.

Ho roala ka hare

Letlapa la valve le nka rabara ea boleng bo holimo bakeng sa ho tiisa ka hare le ka ntle.Theknoloji ea vulcanization ea rabara ea lehae ea boemo ba pele e nolofalletsa poleiti ea valve e vulcanized ho netefatsa litekanyo tse nepahetseng tsa geometri, 'me rabara e hokahane ka thata le heke ea tšepe ea ductile, eo ho seng bonolo ho oela le ho hopola hantle.

Khanyetso ea kutu

'Mele oa valve o koahetsoe ka phofo ea epoxy resin, e ka thibelang ho bola le mafome a' mele oa valve 'me e ka sebelisoa tsamaisong ea likhoerekhoere.

Ha ho bonolo ho robeha

Nakong e fetileng, valve e tloaelehileng ea heke ea tšepe e ne e atisa ho robeha ka lebaka la tšusumetso, ho thulana kapa ho kopana ha lintho tse tsoang linaheng tse ling.Kaha valve e entsoe ka tšepe ea nodular cast, boemo bona bo ka fokotseha haholo.

Tiiso ea "O" e meraro

Hobane kutu ea li-valve e amohela moralo oa ho tiisa oa mehele e meraro ea "0", e ka fokotsa ho hanyetsa likhohlano nakong ea ho chencha, ea fokotsa haholo ts'ebetso ea ho lutla ha metsi le ho nkela selikalikoe sa tiiso ntle le phepelo ea metsi.

E loketseng seno sa bophelo bo botle

Ha bokahare ba 'mele oa valve bo koahetsoe ke resin ea epoxy e se nang chefo, bokaholimo ba ka hare le bo ka ntle ba pheleu bo koahetsoe ka ho feletseng ka rabara e se nang mafome kapa ho senya, e ka sebelisetsoang ho noa e tala.

'Mele oa valve o nepahetseng

'Mele oa li-valve o amohela ho lahla ka mokhoa o nepahetseng,' me tekanyo e nepahetseng ea geometri e etsa hore 'mele oa valve o se ke oa sebetsa ho netefatsa hore valve e tiile.

Boima bo bobebe

Belofo e entsoe ka tšepe ea nodular cast, e ka bang 20% - 30% e bobebe ho feta valve ea heke ea setso.Ho kenya habonolo le tlhokomelo.

Lihlahisoa tse ka sehloohong tsa mollo oa k'hamphani ea ka ke: hlooho ea ho fafatsa, hlooho ea sefafatsi, hlooho ea sefafatsi sa metsi, hlooho ea ho fafatsa foam, ho hatella hlooho ea ho fafatsa kapele, hlooho ea ho fafatsa ka potlako, hlooho ea ho fafatsa bolo, hlooho e patiloeng ea ho fafatsa, hlooho ea fusible alloy sprinkler, joalo-joalo. ho.

Tšehetsa ODM/OEM ho itlhophisa, ho latela litlhoko tsa bareki.

1.Free sampole

2.Keep u nchafatsoa ka kemiso ea tlhahiso ea rona ho netefatsa hore u tseba mokhoa o mong le o mong

3.Shipment sampole bakeng sa ho hlahloba pele ho romelloa

4.Na le mokhoa o phethahetseng oa tšebeletso ea ka mor'a thekiso

Tšebelisano ea nako e telele ea 5., theko e ka fokotsoa

1.Na u moetsi kapa mohoebi?

Re moetsi oa litsebi le mohoebi ka lilemo tse fetang 10, o amohelehile ho re etela.

2.Nka fumana lethathamo la hau joang?

U ka ikopanya le uena ka lengolo-tsoibila, re tla arolelana lethathamo la rona le rona.

3.Nka fumana theko joang?

Ikopanye le rona 'me u re bolelle litlhoko tsa hau, re tla fana ka theko e nepahetseng ka nepo.

4.Nka fumana sampole joang?

Haeba u nka moralo oa rona, sampole e lokolohile 'me u lefa litšenyehelo tsa ho tsamaisa thepa.Haeba u itloaetsa sampole ea moralo oa hau, u tlameha ho lefa litšenyehelo tsa sampole.

5.Na nka ba le meralo e fapaneng?

Ee, o ka ba le meralo e fapaneng, o ka khetha ho tsoa ho moralo oa rona, kapa oa re romella meralo ea hau bakeng sa moetlo.

6.Can u tloaelo paka?

Ee.

Lihlahisoa li tla feta tlhahlobo e tiileng le tlhahlobo pele li tloha fekthering ho felisa tlhahiso ea lihlahisoa tse nang le bokooa

Re na le lisebelisoa tse ngata tsa ts'ebetso tse tsoang kantle ho naha ho ts'ehetsa tlhahiso ea lisebelisoa tse fapaneng tsa ho fafatsa mollo, hardware le polasetiki.